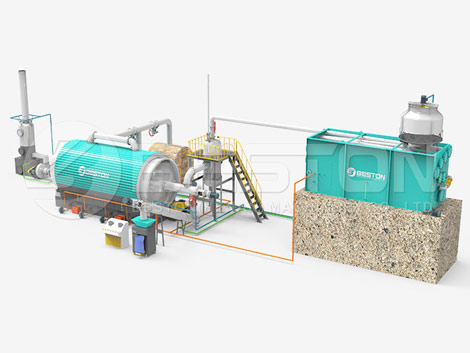

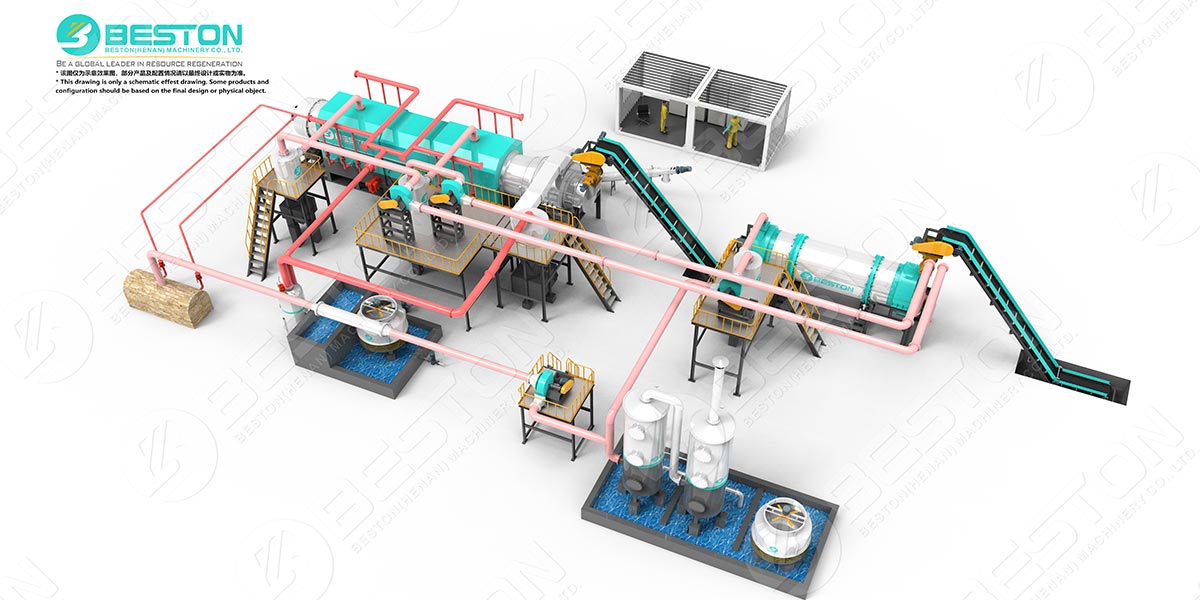

Molded pulp packaging machinery is a highly specialized kind of machine designed to manufacture packaging out of recycled and sustainable raw materials. It utilizes a process that involves the direct formation of multiple packages from biodegradable pulp. Components in the molded pulp packaging machinery are precision-engineered for reliable automation, with both packing speed and capacity being adjustable according to customers’ individual needs. The resulting packages are environmentally-friendly and cost-effective, providing customers with long-term benefits through superior protection during shipping and handling. This advances sustainability trends and supports environmental initiatives at all levels while keeping operational costs low.

Best maintenance tips

Maintaining your molded pulp packaging machinery is essential for limiting downtime and ensuring the longevity of production equipment. Regular inspection and cleaning not only prolongs the lifespan of machinery, but also allows your workers to use them safely. Here are the best ways to maintain your molding machinery:

1. Frequently examine and monitor all parts of the equipment for any warning signs or defects. Change accessories that are worn out in time so as not to cause unnecessary damage to other parts of the egg tray making machine.

2. Keep your molded pulp packaging equipment clean. Regularly clean dust and debris away from chains, belts, motors, and other working parts. This is especially important if you’re using an older model system; keeping it free of dust buildup is a great way to prevent overworking of component parts.

3. Use the correct lubricant for your machine type. Finding the proper lubricant will ensure that your machine is receiving optimum lubrication and reduce the risk of component damage due to friction over time.

Why use molded pulp packaging machinery

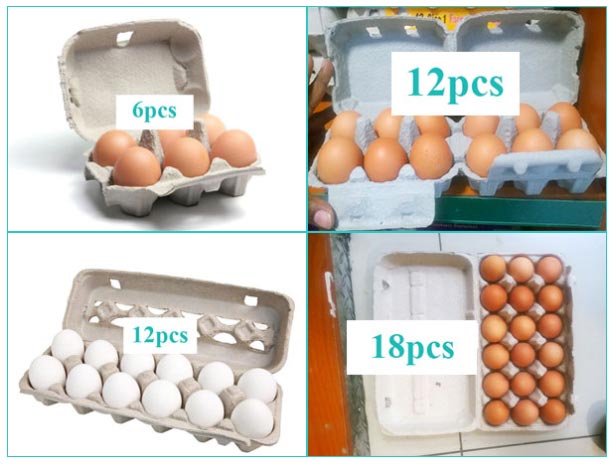

There are numerous benefits of using molded pulp packaging machinery. These machines offer superior production speed and output, with the ability to produce thousands of packages per hour. Additionally, because of the materials used to produce these packages, they are ideal for eco-friendly applications since they are recyclable or compostable: https://pulpmouldingmachines.com/egg-tray-making-machine/automatic/.

Furthermore, this type of packaging can hold heavier items than traditional forms due to its unique design strength that makes it suitable for industrial operations. Operators also benefit from reduced labor costs since the machines require minimal manpower to operate and have low maintenance requirements.

Choosing the right molded pulp packaging machinery

Choosing the right molded pulp packaging machinery for your business is essential in achieving increased efficiency and production speed. In order to make an informed decision, carefully evaluate factors such as the material requirements and desired output of your product. Consider the technology platforms available to find a model that best suits your needs.

Additionally, look into maintenance cycles and warranties to ensure you have access to necessary support and parts should the need arise. Researching and comparing different manufacturers is also a wise choice, so take the time to weigh what each one offers before making your final decision.

It is wise to compare different models from different manufacturers before buying the egg crate making machine for sale. This will help to assess the features of different models and you can accordingly buy one that fits your budget.