You can remove contaminants from various materials through a process known as Thermal Desorption. You can use this process to remove even hazardous waste, besides the normal contaminants like soil, sludge, and sediment. It is an effective method to remove contaminants as it does not require you to use any chemicals or other toxic substances. Thermal desorption is very efficient as it can remove used to remove different contaminants from different materials.

What is thermal desorption?

In the working process of thermal desorption plant, contaminants are removed from materials by heating the contaminated material to a temperature that causes the contaminants to be released into the atmosphere. It can be used to clean contaminated air, soil, or water. You can also use it to remove contaminants from other materials, even clothing.

Setting up a Thermal Desorption Unit

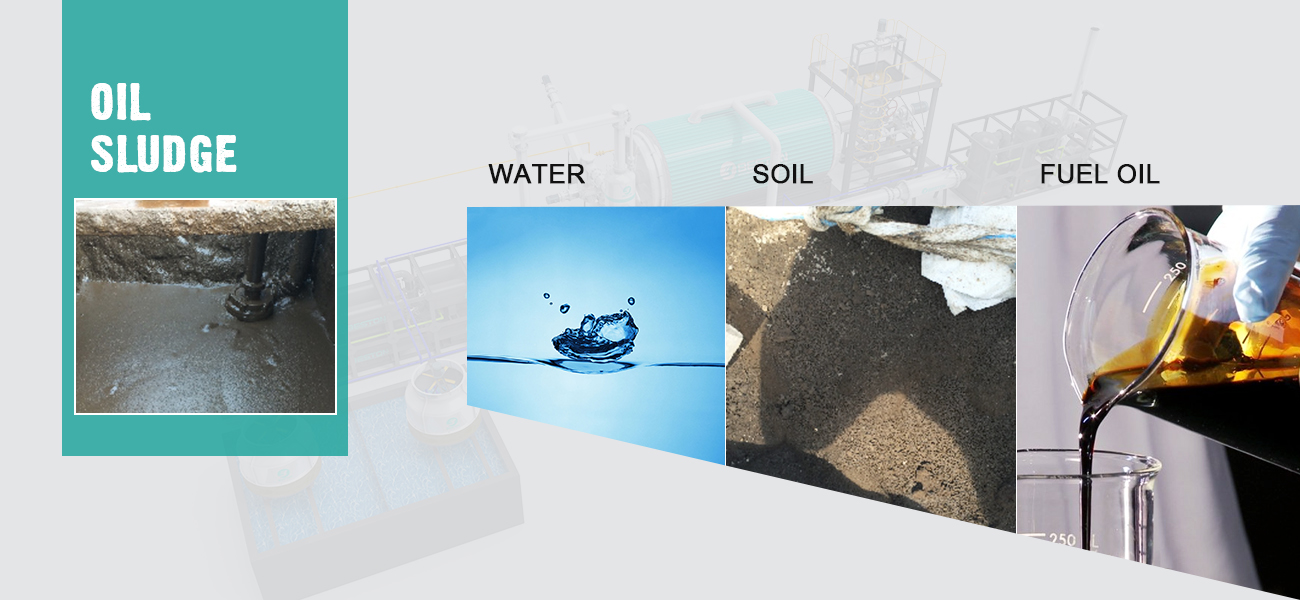

A thermal desorption unit (TDU) is a piece of equipment used in the oil and gas industry to remove hydrocarbons from contaminated soils. The TDU heats the soil to a high temperature, causing the hydrocarbons to vaporize and be drawn off by a vacuum. The TDU can be used to clean up spills, leaks, and other contamination. A thermal desorption unit is used in the oil and gas industry to remove hydrocarbons from contaminated soils by heating the soil to a high temperature and drawing the hydrocarbons off with a vacuum. An oil sludge treatment system can also be used to clean up oil and gasoline spills, leaks, and other contamination. Thermal desorption is a process where the soil is heated to a high temperature in order to vaporize hydrocarbons so they can be drawn off by a vacuum. This process can be used to clean up spills, leaks, and other contamination in the oil and gas industry.

How does a Thermal Desorption Unit Work?

In this process, the removal of contaminants is achieved by heating the material contaminated to high temperatures that cause the contaminants to get vaporized. This vapor is then evacuated, leaving the material clean. Here are more details about this machine: https://bestonasia.com/pyrolysis-plant/continuous/.

How can a Thermal Desorption Unit Help and Benefit You?

Thermal desorption can be an effective way to clean up sites that are contaminated. It is fast and efficient and can be used to clean up a vast variety of contaminants> If you are looking for help in cleaning up a site that is contaminated, then your answer lies in thermal desorption.

Use it to clean up soil that is contaminated or water that has been contaminated. It works by applying high temperatures to the contaminated material, which results in the contaminants being vaporized. This vapor is then evacuated and can then be treated further.

There are many benefits that can come from the use of this small pyrolysis machine for thermal desorption.

- You can use this process to remove contaminants from many surfaces.

- Thermal desorption does not use any chemicals or any other dangerous or toxic cleaning agents.

- It is fast and efficient and takes only minutes to clean any surface.

- Thermal desorption is environmentally friendly and the residue it leaves behind is rarely harmful.

- The technology is extremely versatile and can be applied in many situations