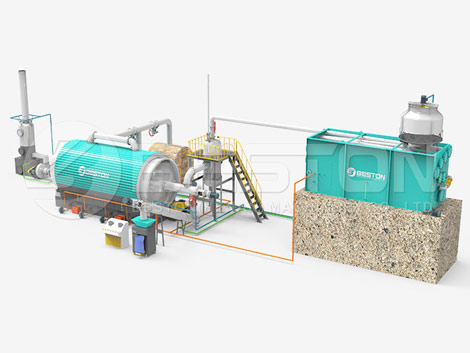

The adoption of continuous tyre pyrolysis plant technology offers numerous advantages for waste management, resource recovery, and environmental sustainability. Unlike traditional batch pyrolysis systems, which operate intermittently and require frequent manual intervention, continuous pyrolysis plants offer a continuous and automated process for converting waste tyres into valuable products such as fuel oil, carbon black, and steel wire. In this comprehensive analysis, we delve into the key advantages of continuous tyre pyrolysis plants, highlighting their efficiency, scalability, and environmental benefits.

1. Continuous Operation

Continuous tyre pyrolysis plants operate continuously, without the need for frequent shutdowns or manual intervention. This continuous operation allows for uninterrupted processing of waste tyres, maximizing throughput and productivity while minimizing downtime and labor requirements. By eliminating the need for batch loading and unloading, fully continuous pyrolysis plant streamline the pyrolysis process, ensuring consistent product quality and process efficiency.

2. Enhanced Efficiency

The continuous operation of continuous tyre pyrolysis plants results in enhanced process efficiency and energy utilization. Unlike batch systems, which require heating and cooling cycles for each batch of feedstock, continuous pyrolysis plants maintain steady-state conditions, optimizing heat transfer and energy recovery. This enhanced efficiency translates into higher yields of valuable products, such as fuel oil and carbon black, while reducing energy consumption and operating costs.

3. Scalability

Continuous tyre pyrolysis plants offer scalability and flexibility to meet varying production demands and processing capacities. These plants can be easily scaled up or down by adjusting the feed rate, reactor size, and process parameters to accommodate different feedstock volumes and composition. Whether processing small batches or large quantities of waste tyres, continuous tyre pyrolysis plant can be tailored to suit specific requirements, making them suitable for a wide range of applications and industries.

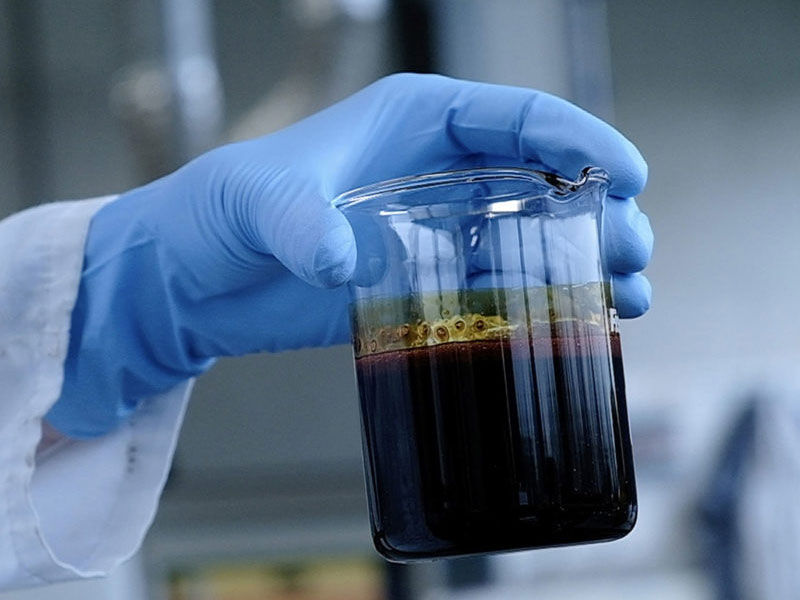

4. Improved Product Quality

The continuous operation and precise control offered by continuous tyre pyrolysis plants result in improved product quality and consistency. By maintaining optimal process conditions, such as temperature, residence time, and heating rate, these plants produce high-quality fuel oil, carbon black, and steel wire with minimal impurities and contaminants. This ensures that the end products meet stringent quality standards and specifications, enhancing their market value and usability in various industrial applications.

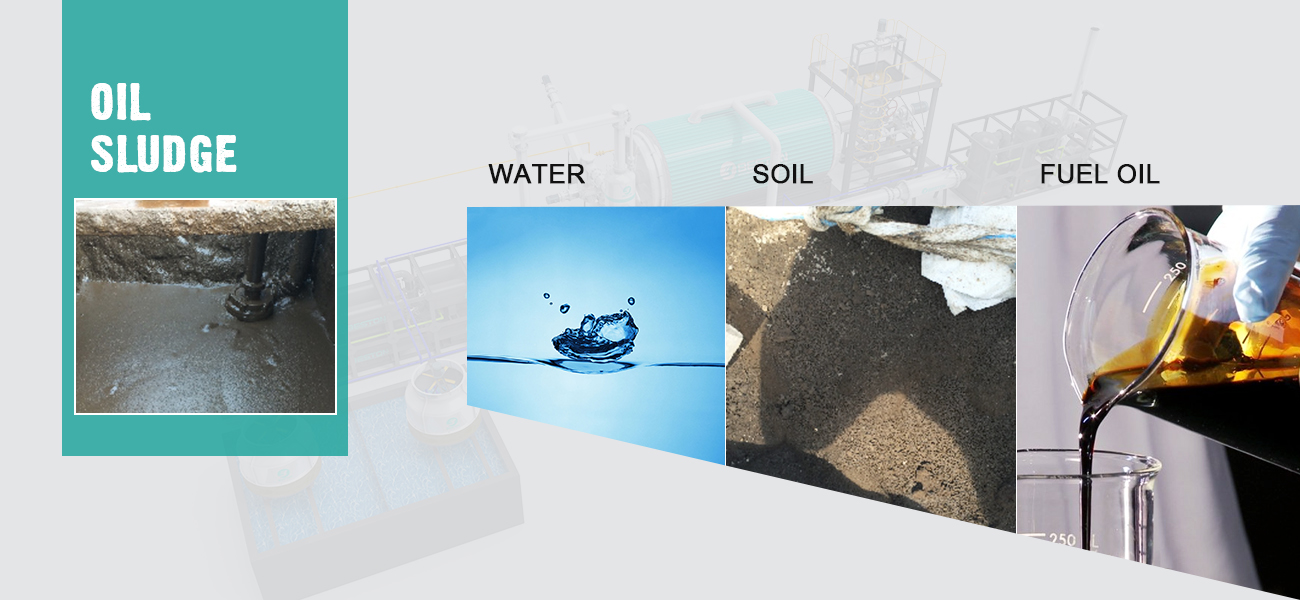

5. Reduced Environmental Impact

Continuous tyre pyrolysis plants contribute to environmental sustainability by reducing the environmental impact of waste tyre disposal and resource extraction. By converting waste tyres into valuable products through pyrolysis, these plants mitigate the need for landfilling or incineration, reducing greenhouse gas emissions, soil contamination, and resource depletion associated with traditional waste management practices. Additionally, the recovery of fuel oil and carbon black from waste tyres helps offset the demand for virgin fossil fuels and carbon-intensive materials, further reducing environmental footprint and promoting circular economy principles. If you would like to know more information about emission treatment, please contact Beston Group Co., Ltd..

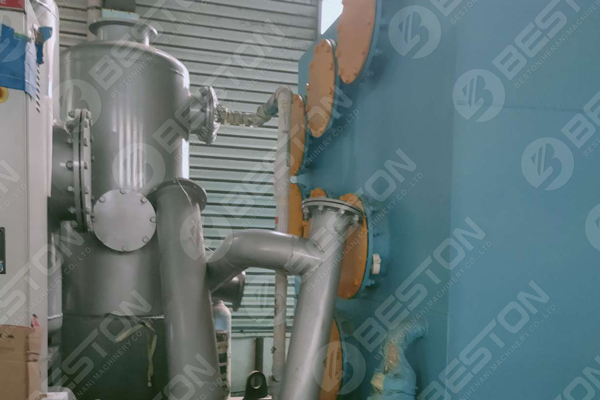

6. Minimal Operator Intervention

Continuous pyrolysis plants require minimal operator intervention, thanks to their automated operation and integrated control systems. Operators can monitor and control the pyrolysis process remotely through advanced supervisory control and data acquisition (SCADA) systems, minimizing the need for onsite supervision and manual adjustments. This reduces labor costs, enhances operational safety, and allows operators to focus on other tasks, maximizing productivity and efficiency.

7. Compliance with Regulations

The continuous tyre pyrolysis plant is designed to comply with stringent environmental regulations and safety standards governing waste management and industrial processes. By incorporating advanced emission control systems, waste heat recovery units, and safety features, these plants ensure compliance with regulatory requirements and minimize environmental impact. This helps operators avoid fines, penalties, and legal liabilities associated with non-compliance, ensuring responsible and sustainable operation of pyrolysis facilities.

Conclusion

In conclusion, continuous tyre pyrolysis plants offer a host of advantages over traditional batch pyrolysis systems, including continuous operation, enhanced efficiency, scalability, improved product quality, reduced environmental impact, minimal operator intervention, and compliance with regulations. These plants represent a sustainable and cost-effective solution for converting waste tyres into valuable products, contributing to waste reduction, resource recovery, and environmental conservation. As the demand for waste-to-energy solutions continues to grow, continuous pyrolysis plants stand out as a viable option for addressing the global challenge of waste management while creating economic opportunities and promoting environmental sustainability.