Plastic waste has become a significant environmental concern, necessitating innovative solutions for its effective management. Waste plastic pyrolysis plants offer a promising approach to address this issue by converting plastic waste into valuable resources through the process of pyrolysis. In this article, we will explore the concept of a waste plastic pyrolysis plant, its significance in tackling plastic waste, and delve into the intricacies of the pyrolysis process.

The Pyrolysis Process

Pyrolysis is a process in thermal desorption unit that breaks down organic materials, such as plastic, in the absence of oxygen. By subjecting waste plastics to high temperatures, typically between 300°C and 800°C, the polymer chains are broken down into smaller hydrocarbon molecules. Various types of waste plastics, including polyethylene, polypropylene, and polystyrene, can be suitable for pyrolysis.

The pyrolysis process is influenced by several factors, including temperature, heating rate, residence time, and the presence of catalysts and additives. The temperature and heating rate determine the rate of decomposition, while the residence time and reaction time affect the yield and quality of the end products. Catalysts and additives can enhance the process efficiency and yield specific desired products.

Design and Components of a Waste Plastic Pyrolysis Plant

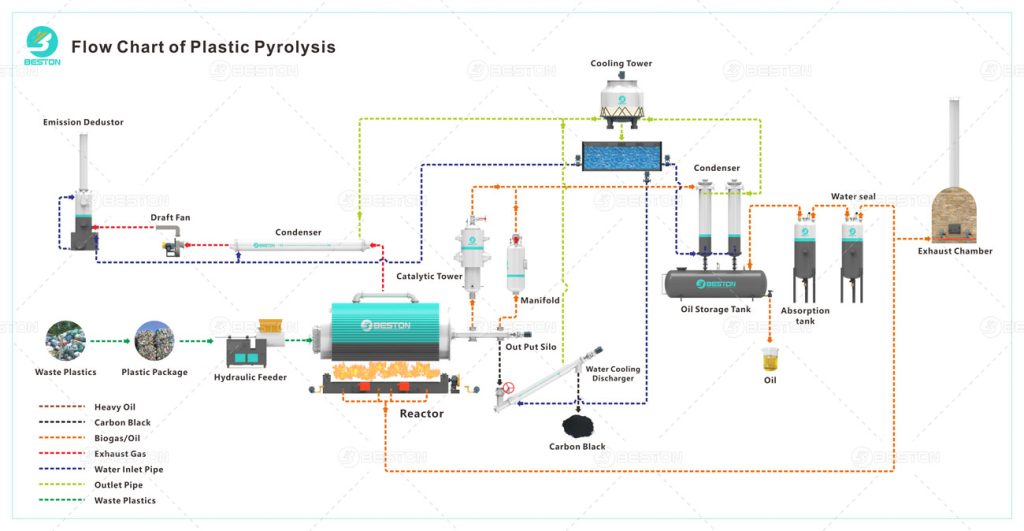

A waste plastic pyrolysis plant consists of several key components, each playing a crucial role in the pyrolysis process. The reactor vessel, typically made of high-quality steel, provides a controlled environment for the thermal decomposition of waste plastics. It is equipped with a heating system, which may use various energy sources such as direct combustion, electrical heaters, or microwaves.

The gas and oil separation unit is responsible for separating the gaseous products, such as hydrocarbon gases, from the liquid and solid fractions. The condensation system then cools down the gaseous products, facilitating their transformation into valuable liquids, commonly referred to as pyrolysis oil. The emission control system ensures the removal of harmful pollutants and particulate matter, safeguarding the environment.

Benefits and Potential Applications

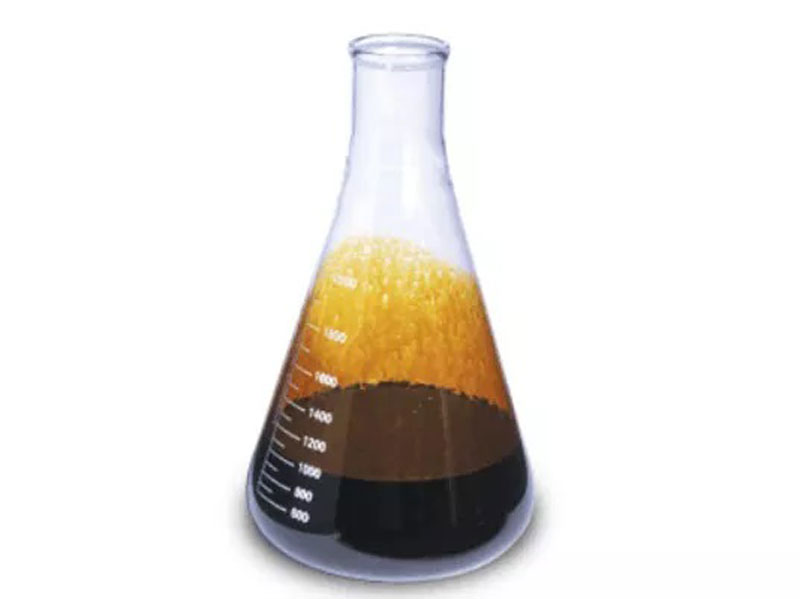

Waste plastic pyrolysis plant offers a range of benefits and potential applications. The primary output, pyrolysis oil, can be used as a substitute for conventional fossil fuels in various industrial processes, such as power generation or as a feedstock for refineries. Carbon black, another valuable byproduct, finds applications in the rubber and ink industries. The produced gas can be utilized for heating or powering the pyrolysis plant itself.

Beyond the economic advantages, pyrolysis plant for sale contributes significantly to environmental preservation. By diverting plastic waste from landfills and incineration, these plants help reduce greenhouse gas emissions and conserve natural resources. Furthermore, they present opportunities for waste management and resource recovery, fostering a circular economy approach.

Challenges and Limitations

While waste plastic pyrolysis plants offer immense potential, they also face several challenges and limitations. The quality and variability of plastic feedstock can affect the pyrolysis process, requiring careful sorting and preparation of the waste plastics. Emissions and air pollution control pose challenges as well, demanding effective filtration and treatment systems to minimize environmental impact.

The economic viability and scalability of waste plastic pyrolysis plants need to be carefully assessed, considering factors such as initial capital investment, operational costs, and market demand for the end products. Additionally, regulatory and legal considerations, including permits and compliance with waste management regulations, can pose hurdles that need to be addressed for successful plant operation. Welcome to consult Beston Group for more details about plastic pyrolysis. You also can visit our website: https://bestonasia.com

Conclusion

Waste plastic pyrolysis plants represent a promising solution to combat the growing problem of plastic waste. Through the pyrolysis process, these plants convert waste plastics into valuable resources, including pyrolysis oil, carbon black, and gas, while offering environmental benefits and contributing to a sustainable waste management system. Although challenges exist, ongoing advancements and increased awareness create opportunities for waste plastic pyrolysis plants to make a substantial impact in plastic waste management and resource recovery.